This forum seems like it has many helpful members, especially mangozac. I feel a little cheeky having my first post be such a request, but I would be very appreciative of any help!

So much helpful info and discussion here, you can be sure I'll be hanging around anyway!

I am starting to do resin casting from 3D printed parts (commissions accepted

I've acquired a Wolf Sioux 25 compressor and .

My problem is that the documentation of both items is appalling and my knowledge is similarly basic so I don't know what fittings to go for.

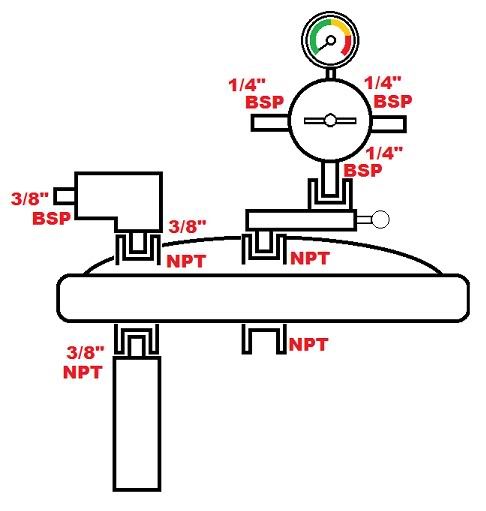

The image below shows the changes I intend to make.

I would like to know what kind of fittings I should use and what size they would need to be. I have measured the connections but am still a little unsure whether they are imperial or metric. mangozac mentioned this in and seems to have the same tank as me.

The compressor has s but what type are they? They look to me like series25 but, like I say, I'm new to all this.

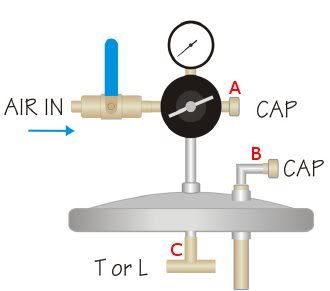

A seems to be .5" male and B is .64" male (is this 5/8"?). I'd like to just remove the right-angle fitting on B if I can and plug the hole. Measurement looks the same.

C is pretty much optional (prevents air disturbing the molds) but is .32" (5/16"?).

I can provide measurements in mm too.

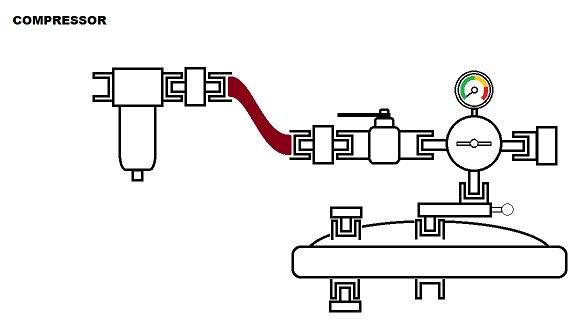

I also need to add the ball valve and an adaptor to connect it to the compressor.

Can anyone recommend an inexpensive water filter too?

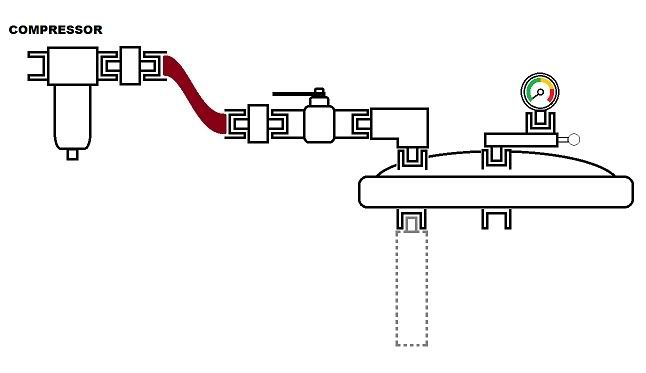

I've seen people on removing the whole outlet section that comes fitted to the compressor and attaching their own parts to the hole at the end of the tank. I am slightly worried about parts sticking out like that and the filter hitting the floor so would probably prefer to avoid that approach.

I have no real urge to preserve the dual outlet.

Many thanks for any help!